Heavy Duty Machining Portfolio & Project Gallery

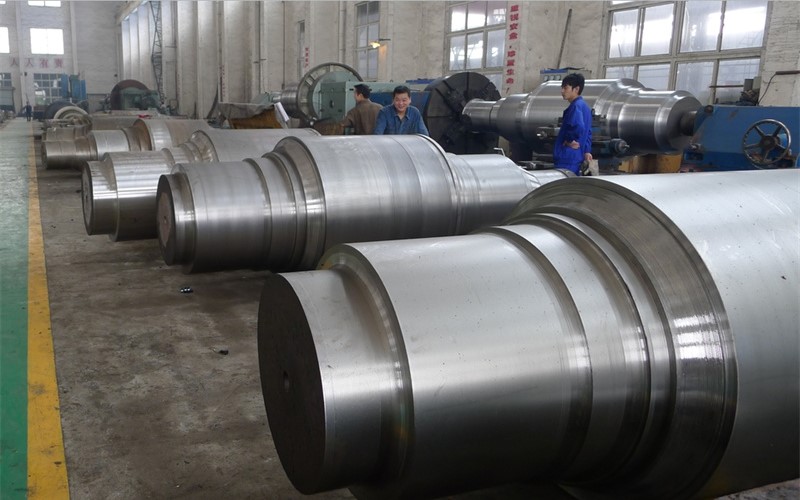

Steel Rolling Mill Shaft

Track Roller

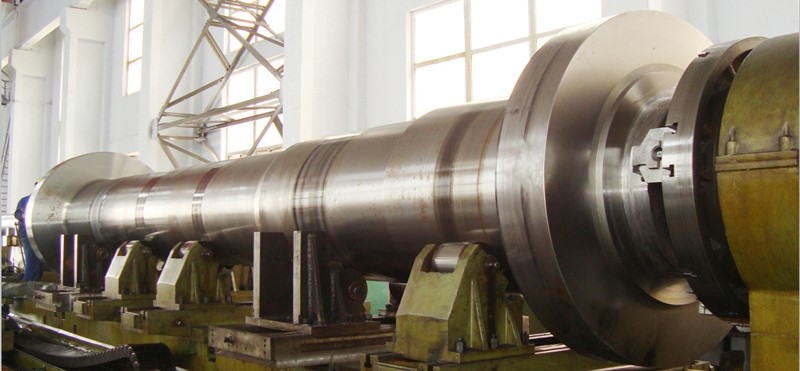

Steel Rolling Mill Shaft Under Machining

Cement Plant Shaft

Large Motor Shaft

16-Meter-Long Precision-Finished Part

Rough-Machined Part With 1.5M Diameter And 10M Length

Hydroelectric Power Plant Component

Large Part Machining Services provide specialized manufacturing solutions for components that are too big or heavy for standard machine tools. This field is critical for industries such as energy (power generation, oil & gas), aerospace, defense, mining, and heavy industrial equipment, where components can weigh several tons and measure many meters in length or diameter. Our services blend massive machine capacity with micron-level precision.

The mechanical machining process for large metal parts is a multi-stage, carefully managed workflow:

Preparation and Rough Machining: The process typically begins with a large raw workpiece, such as a forging, casting, or thick plate of steel, stainless steel, or aluminum. The first step is rough machining, where excess material is removed efficiently. This is often performed on powerful CNC horizontal boring mills (HBMs) or vertical turning lathes (VTLs) to quickly bring the part closer to its final shape and relieve internal stresses from the raw material.

Semi-Finishing and Feature Machining: Once the bulk of the material is removed, the part is transferred for more precise operations. Our large-capacity CNC machines, including 5-axis gantry mills and floor-type boring mills, are used to machine complex features. This includes milling large flat surfaces, boring precise holes and internal diameters, and creating intricate contours. For large cylindrical parts like shafts or rings, our VTLs perform precision turning, facing, and grooving operations.

Finishing and Quality Assurance: The final stage focuses on achieving the exact tolerances and surface finishes specified in the design. This may involve precision grinding, honing, or finish milling. Throughout the entire process, quality control is paramount. We utilize large-scale metrology equipment, such as laser trackers and large-envelope Coordinate Measuring Machines (CMMs), to verify dimensional accuracy at every critical step, ensuring the final part meets all engineering requirements.

Ultimately, our expertise in Large Part Machining Services lies in our ability to handle immense scale without compromising on the precision that modern industries demand.