Custom Heavy Forging & Heat Treatment Services

10,000-Ton Forging Press

5,000-Ton Forging Press

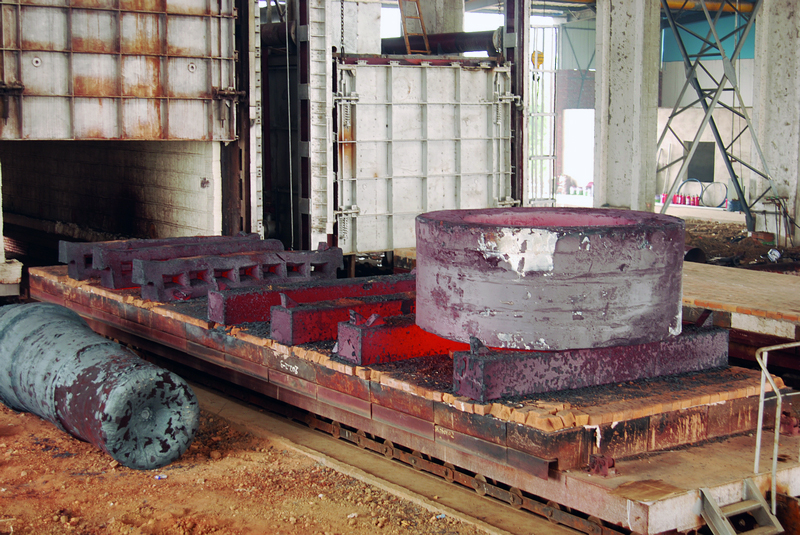

Forging Part (in progress )

Heat-Treated Part

Heat Treatment Furnace

Large Quench Tank

Heavy Forging & Heat Treatment Services are an integrated manufacturing discipline essential for producing large, high-strength metal components for the world’s most demanding industries. This combination ensures that parts not only achieve their required shape but also possess the precise metallurgical properties needed for safety and long-term performance in critical applications like power generation, shipbuilding, mining, and oil & gas.

Phase 1: Heavy Forging with Large-Scale Presses

The process begins with open-die forging, a method ideal for custom, large-scale parts. We start with a heated steel ingot, which can weigh up to several hundred tons.

Equipment: The primary machine is a multi-thousand-ton hydraulic forging press. This equipment exerts immense compressive force to shape the metal. The ingot is precisely handled and positioned between forging dies by a large, rail-bound or mobile forging manipulator.

Process: Through a series of controlled compressions, the manipulator and press work in concert to knead the metal, refining its internal grain structure, closing any internal voids, and shaping it into a desired form—such as a large-diameter shaft, a seamless ring, a heavy block, or a custom disc. This process imparts superior strength, toughness, and fatigue resistance compared to casting or machining from plate.

Phase 2: Precision Heat Treatment

After forging, heat treatment is the critical subsequent step to optimize the mechanical properties of the component.

Equipment: This is performed in large-capacity, computer-controlled furnaces that ensure uniform heating to precise temperatures, and large-scale quench tanks filled with water, polymer, or oil for controlled, rapid cooling.

Processes: Common cycles include:

Normalizing: Heating and air-cooling to refine the grain structure post-forging.

Quenching: Rapidly cooling from a high temperature to achieve maximum hardness and strength.

Tempering: Reheating the quenched part to a lower temperature to reduce brittleness and develop the final desired balance of hardness and toughness. This combined “Quench and Temper” (Q&T) process is fundamental for high-performance parts.

By offering Heavy Forging & Heat Treatment Services as a single-source solution, we maintain complete control over the entire manufacturing process, guaranteeing components of the highest integrity.